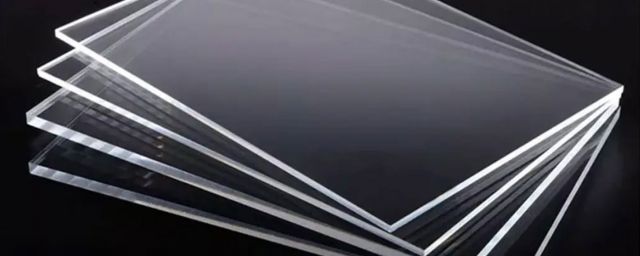

Acrylic plate is a kind of chemical material, which is a kind of specially treated organic glass. Acrylic raw materials generally appear in the form of particles, plates, pipes, etc., with pure and rich colors, and are most widely used in light boxes. Acrylic plate can be combined with aluminum plastic plate profiles to meet the needs of businesses. The light box made of acrylic plate has the characteristics of good light transmission, rich colors, long service life, etc.

Precautions for Acrylic Plate

Acrylic plates are not resistant to high temperatures. Generally, the high temperature resistance of acrylic plate is not high, and it can only withstand the high temperature below 85 ℃. Although many manufacturers have said that the acrylic plate can withstand 104 degrees of high temperature, when the acrylic plate stays in an environment where the temperature exceeds 60 degrees to 95 degrees for a long time, the acrylic plate is prone to slight deformation.

When the acrylic plate is processed, if the temperature exceeds 96 ° C, then the thermal deformation can be started. In the process of using the acrylic plate, if the ambient temperature is too high, it will easily lead to the deformation of the acrylic plate, and the deformation severity of the acrylic plate will generally have a great relationship with the actual thickness of the acrylic plate. The thinner the acrylic plate, the more serious the deformation will be, and the thicker the acrylic plate, the smaller the deformation will be.

In the process of using the acrylic plate, it is not allowed to store the acrylic plate and other organic solvents in the same location, let alone let the acrylic plate contact the organic solvent. In the process of transporting the acrylic plate, it is absolutely not allowed to tear off and wipe off the protective film on the surface of the acrylic plate, otherwise the surface of the acrylic plate may be damaged.

When cleaning the acrylic plate, it is absolutely not allowed to use hard objects to wipe on the surface of the acrylic plate, and it is also not allowed to use dry wiping to clean the acrylic plate, otherwise the surface of the acrylic plate will be easily scratched, which will affect the overall beauty of the acrylic plate.

What tool is used to cut the acrylic plate?

Machinery: common tools are carving machines, electric saws, and laser cutting machines. These tools can cut very well, saving time and labor.

Manual type: manual cutting of acrylic boards requires the use of hook knife. The board shall be planned in advance, and then cut to half of the board with hook knife, and then break it by hand.

Acrylic plate bending. The sheet is softened by air blast oven, but it can be formed when the temperature is between 140 ℃ and 160 ℃. Find a small angle iron, which must be consistent with the length of the acrylic plate to be bent. Fix the angle iron on the acrylic plate with a clamp, and put it into the boiling water together, or blow it along the right angle side of the angle iron with an electric hair dryer, and then put it on the plane to press and hold it tightly.

How much temperature can acrylic resist without deformation?

Although its glass transition temperature reaches 104 ℃, the maximum continuous use temperature varies from 65 ℃ to 95 ℃ depending on the working conditions. The thermal deformation temperature is about 96 ℃, and the Vicat softening point is about 113 ℃. The heat resistance can be improved by copolymerizing the monomer with propylene methacrylate or ethylene glycol acrylate diester.

The cold resistance of polymethyl methacrylate is also poor, and the embrittlement temperature is about 9.2 ℃. The thermal stability of polymethylmethacrylate is medium, superior to PVC and POM, but inferior to polyolefin and polystyrene. Its thermal decomposition temperature is slightly higher than 270 ℃, and its flow temperature is about 160 ℃, so there is still a wide range of melting processing temperature.