Whether your family walks over them or your pets chew on them, electrical cords wear out over time. Getting replacement cords can be expensive, but fortunately you can fix most cords on your own for a fraction of the price. No matter how you plan on doing the repair, cut off the damaged portion first. For a simple, straightforward way to repair a cord, fit it with a new plug. If you can’t find a new plug and wish to preserve the cord’s length, you could apply metal solder with a soldering iron for a stronger fix. Then, plug in your repaired cord to see that it works as well as a new one again.

Exposing Damaged Wires

Disconnect the cord from the outlet.

Make sure it is completely unplugged before working on it. When it is plugged into an outlet, it still has an electrical current running through it. Be careful to avoid touching any exposed metal wires or contacts while unplugging the cord. Detach any other cords or electronics connected to the wire as well.

- If you’re dealing with heavily-damaged cords, consider shutting off the electricity first. Shut off the fuse or circuit breaker. It is usually located in a secluded spot like in the basement or a storage room.

Inspect the cord for broken wires and other signs of damage.

Feel the entire length of the cord to see if it feels unusually warm. Look for any breaks in the insulation that could prevent the cord from working. Also, check plug prongs to see if they look melted or burned.

- Consider marking any damaged areas so you don’t have to search for them later. If you see a lot of serious damage, you may be better off purchasing a new cord instead of attempting a repair.

- Note that broken extension cords cannot safely be spliced, or joined, back together. No matter how well you try to reconnect the old wires, the cord won’t be safe for use. Instead, fit it with a new plug.

Repair superficial damage by wrapping it with electrical tape.

Take the edge of the tape and place it over the broken casing. Then, wrap the tape around the cord a few times to seal the damage. Make sure it’s well-sealed, then treat other damaged portions the same way. Electrical tape is a type of black vinyl that resists electricity, so it’s great for safely wrapping up cords as long as there aren’t any exposed metal wires.

- If the cord is so damaged that you see frayed metal, then you will most likely have to cut it to repair it. Tape is only good for insulating wires, preventing existing superficial damage to prevent it from getting worse.

- Another option is to fit a PVC shrink tube over the damaged portion. Heat it gently to shrink it and seal off the break.

- Other types of tape, including duct tape, can work. However, electrical tape is the best choice because it is designed to work on electrical components.

Cut the cord on both sides of the damaged portion using pliers.

End cutting pliers and lineman’s pliers are a couple of options for cutting cleanly through electrical cords. Position the pliers past the damaged portion and sever the cord. Cut through all of the insulation and wiring with a single attempt. Then, do the same on the opposite side of the damaged portion to completely remove it.

- Check the length of each remaining cord. If they are pretty long, you may be able to reuse both of them. Throw away cut lengths that are too short to be useful.

- For example, you might cut an extension cord in half and reuse both parts. For smaller cords, such as from electronic devices, you may not need the shorter part even if it’s reusable.

Strip about 1 in (2.5 cm) of insulation off the cord with wire strippers.

Wire strippers are very useful for removing the cord’s outer casing without damaging the wires underneath it. Measure from the cut end of the wire, taking caution to avoid removing more of the insulated casing than you need to. Clamp the pliers down to break the insulation, then slide it off the wire. Repeat this with the other half of the cut cord if you plan on soldering the pieces back together

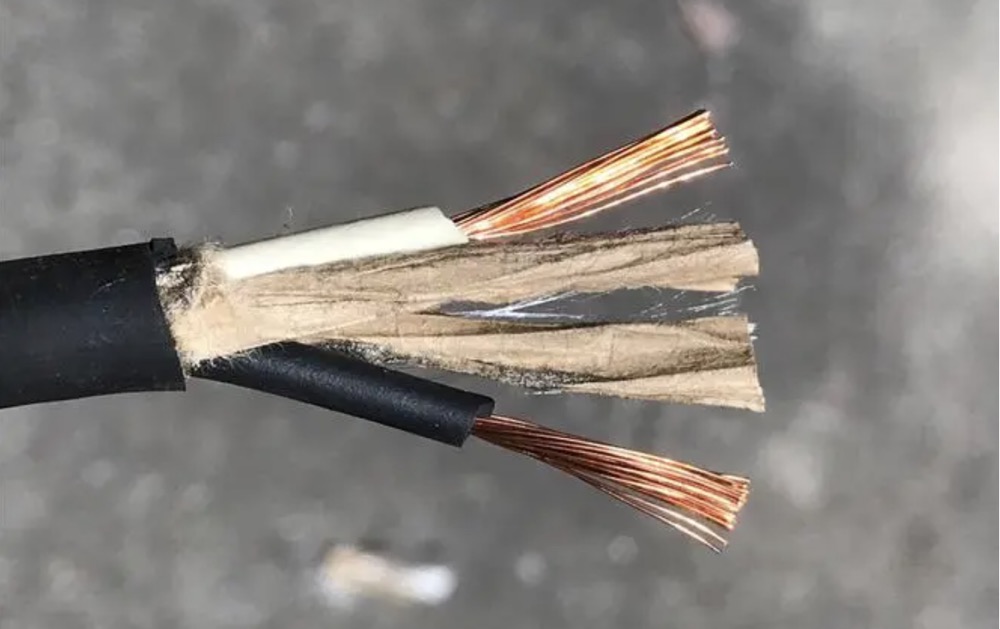

- This will reveal the electrical wires inside the cord. Expect to see 3 wires in thicker cords like extension cords. Smaller cords, such as for household accessories, contain fewer wires.

- If you don’t have wire strippers available, you could use a utility knife or another sharp tool. However, be very careful to avoid damaging the electrical wires. Score the insulation until you are able to remove it from the cord.

- If you are stripping wire for the first time, use the correct measurements.

- If you do the AWG, the American Wire Gauge, and a number 12 wire, you have to put it on the number 12 slot on the stripper.

- It will give you a perfectly stranded or stripped wire.

Remove insulation from each of the wires inside the cord.

Measure about 3⁄4 in (1.9 cm) from the cut end of each wire. Then, use the wire strippers to break through the casing. Slide the cut insulation off when you’re done. It will expose the copper wires, which you can reroute to your replacement cap.

- The wires are a little smaller than the cord, so use wire strippers if you have them. Wire strippers are a better choice for precision than other tools, such as a utility knife, which can easily ruin the wires.

- If you make a mistake and cut through the individual wires, don’t worry. Your cord isn’t ruined. Just cut out the damaged portion again.

- If you’re planning on soldering the cord lengths back together, strip the wires inside both parts.

Installing a New Plug

Select a new plug with the same number of prongs as the old one.

Fixing a cord without soldering involves installing a new plug. The new plug has to match the old one, but there are various types of plugs. Try to get an identical plug that is the same shape and has the same number of prongs. Match the amp rating as well, which will likely be printed on the plugs.

- Installing a new plug is the simplest solution for most types of cords, including extension cords. However, for some accessory cords, you may not be able to find or install a matching plug. Try soldering instead.

- Take the plug with you to a home improvement store to help find a matching replacement. Sometimes you can pull the plug off or unscrew it from the old cord.

- Many appliances and older extension cords use what is known as polarized cords and caps. The caps connect to a flat 2-wire cord. To identify it, look for a ridge along the length of the cord, printed identifying information on the cord, or gold and silver conductors on the plug.

- Plugs can be purchased online or at home improvement stores along with all the other tools needed for the repair.

Inspect the replacement cord cap for labels showing where each wire fits.

Cord caps have several different slots with screws used to hold the wires in place. These slots can vary depending on the kind of cap you’re using. The slots may have labels like “black” and “white” that correspond to the wires inside the electrical cord. Match the labels to the color of the insulation on each wire.

- If the cap doesn’t have labels, check the screws. The black power wire connects to the orange brass screw. The white neutral wire connects to the silver screw. Finally, the green ground wire connects to the green screw.

- Note that the wire colors may differ depending on the cord or electrical code in your area. For example, in Europe, the power wire is often brown or black. Blue is for the neutral wire, while yellow and green are for the ground wire.

- The wires have to be plugged into the proper spots in order for the cord to work correctly. Putting them in the wrong places is dangerous! It could damage electronic devices or even increase the risk of electrical shock.

Tuck the ends of the exposed wires clockwise around the screws.

Work on the wires 1 at a time, connecting them to the appropriate cap terminals. Keep each wire secure by twisting the exposed strands together first. Then, begin wrapping the wires clockwise around the screws. Most plugs have small notches you can use to hold the wires in position, keeping them close to the screws.

- Make sure all the wire strands have been twisted together and are secured under their respective terminals. If they are loose, they could cause the cord to short circuit.

- The exposed parts of the wires cannot touch one another. If they are touching, tuck them in closely against the cap and screws before using the cord.

Turn the screws clockwise to pin the wires to the cap.

Use a Phillips screwdriver on each screw. Once you tighten the screws, you won’t be able to move the wires. Check them over to make sure they are well-positioned and secure. If you need to make adjustments, loosen the screws by turning them counterclockwise.

- Check your work before moving on. Any wire strands still outside of the screw terminals are a problem. You might damage them by attempting to fit the other half of the plug over them.

Fit the plug housing over the cap and screw it in place.

Slide the other half of the plug along the cord and onto the cap. It will fit over the cap, keeping the wires well-protected. Inspect the outside portion of the housing for a small hole where you can fit a screw. Place the screw that came included with the new plug, then turn it clockwise to tighten it.

- Take care not to overtighten the screw connector. It could crush the plug casing or the wires inside, creating a new hazard for anyone that comes into contact with it. Tighten it just enough to keep the plug halves secure.

Test the cord by plugging it into a functional outlet.

If possible, shut off power to the outlet before plugging in the repaired cord. Make sure you deactivate power to the room or circuit where you plan on using the cord. Then, turn it back on once you’re ready for the test. Stay away from the repaired portion until you’re sure the cord is working without issue. If you don’t see anything unusual, then the repair was a success!

- If you notice a hissing sound, smoke, or other problems, shut off the power right away. For your own safety, do not touch the cord until you have deactivated the power.

- If the cord doesn’t work and you’re sure you repaired it correctly, the problem could be the outlet. Outlets wear out over time and need to be replaced so the metal contacts firmly connect to the plug.

Splicing Wires

Set up a ventilated work space that is heat-resistant, if possible.

Choose a spot with a ventilation fan or at least some windows you can open to let out any smoke from the soldering iron. Use a fire-safe table or workbench to protect against burns from the metal solder and soldering iron. If you have a stainless steel or ceramic surface, you can use it. Another option is to spread a heat-resistant material, such as a glass soldering mat, where you plan on repairing the cord.

- Keep a cover and stand for the soldering iron nearby. That way, you don’t have to worry about it touching and damaging your work surface.

- Tile, brick, and stone are a couple of types of scrap metal you can use to protect tables from dripping metal. Most materials are safe to use as long as you keep the soldering iron from them.

- Soldering is a great way to repair valuable cords when you don’t want to buy a new plug or can’t find a suitable one. It works for all types of cords, but it’s often best for single-wire cords with a permanently-attached plug.

Slip a PVC shrink tube over the wire to use later.

A PVC shrink tube is like a piece of plastic that protects and insulates exposed wires. They come in different sizes, so choose one that is at least as big as the area you wish to repair. A 1 in (2.5 cm) tube is enough for most repairs. After choosing a tube, slide it along one of the cords so it’s out of the way, leaving the cut and stripped wires exposed.

- If you don’t put the tube on the cord now, you won’t be able to do it later. Make sure you get one that is the proper size for the repair!

- The tubes and other material needed for the repair are available online or at most hardware stores.

Select 63/37 lead solder for an easy material to work with.

Solder is a type of metal used to join wires together. A 63/37 solder wire is made of 63% tin and 37% lead, which both melt at a low temperature for a quick but strong fix. It melts at about 361 °F (183 °C). It’s beginner-friendly and often used to repair electronics.

- Note that you may find solder with other percentages. They are all slightly different. Although they can be used, stick to a 63/37 lead solder wire for a straightforward repair.

- There are also lead-free solder wires. These wires are environmentally safe but melt at a higher temperature. If you decide to use one, note that it melts at a temperature about 50°F (30°C) higher than lead solder.

Put on a pair of safety glasses before operating a soldering iron.

Wear the glasses for protection in case the melted metal splashes on you. Also, consider wearing a long-sleeved shirt, long pants, and closed-toe shoes for additional protection. Cover up as much as possible to avoid burns!

- Be aware of the smoke released during the soldering process, especially if you’re working with lead. Work outdoors or in an otherwise ventilated area while wearing a dust mask.

- Keep other people and pets out of the area until you’re finished and have given the soldering iron plenty of time to cool off.

Twist the exposed ends of the cord’s internal wires together.

Cut out the damaged portion and strip the wires before doing this. Then, match the wires inside the severed cord according to the color of their insulation. Depending on the cord you’re fixing, you might see more than 1 color, such as red and blue. Twist the red wires together, then twist the blue wires together, keeping the colors separate.

- Note that thicker cords, such as extension cords, have more than 1 internal wire. The wire colors have to match or else you could short-circuit the system. Smaller cords, such as your average lamp cord or phone charger, only have 1 wire.

- It is possible to solder wires by laying the exposed ends side by side. However, it’s usually easier to twist them together and then coat them with solder.

Melt solder

Hold the tip of the solder wire at a 45-degree angle above the exposed wires. Then, raise the heated soldering iron up toward the wire, holding it at an opposite 45-degree angle. Gently melt the soldering material so it drips onto the exposed wires. Keep moving the solder wire and soldering iron back and forth until the exposed wires are coated in the solder.

- The goal is to melt the soldering material, not the repaired wires. To avoid melting them, don’t let the soldering iron linger in one spot. Also, avoid touching it to the wires.

- You could get a soldering pencil instead of a regular soldering iron. It is smaller and easier to control, which can be important when working with small wires. Hold it like a pencil.

Let the soldered wires cool for about 2 minutes.

Leave them alone until they become cool to the touch. While the repair cools, turn off your soldering iron and set it aside in a safe spot, such as a holder. Keep the repaired cord undisturbed so the solder sets properly.

- If the solder doesn’t have time to cool, it will be too brittle and the wires may come apart again.

Heat the PVC tube gently after sliding it over the solder.

Move the PVC tube down cord, positioning it so it completely covers the repaired area. To keep it from burning, get a hair dryer or another source of gentle but consistent warmth. Hold it about 5 in (13 cm) back from the cord. Move it back and forth to heat the tube until it shrinks and fits tightly over the soldered area.

- If you don’t have a hair dryer or a heat gun, you could try using a lighter. Be very careful to avoid burning the tube.

Test the cord by plugging it into an electrical outlet.

Shut off the electricity to the outlet by flipping the corresponding switch in your home’s fuse or circuit breaker box. Then, plug the wire in and reactivate the electricity. Watch the wire for smoke or other problems. If it seems to be working without a problem, then consider it repaired.

- Turn off the electricity right away if you notice hissing or other problems. Continuing to use the cord could lead to a fire or electrical shock. You most likely will need to replace it.

Tips

- You can test cords by using a continuity tester or multimeter. Use the testing probes to look for a continuity of 0 ohms, indicating that the repaired cord is working properly.

- If you have a long cord, you can cut it and turn it into a pair of smaller cords. If you’re left with a short length after cutting off the damage, then you’re often better off throwing it away.

- Always check to make sure you’re using the right plug for the cord you’re fixing. If you use the wrong type of plug, it could cause electrical damage to the wires.

Warnings

- According to the National Electrical Code, splicing extension cords is unsafe. Repairs can only be done by cutting out the damaged portion and fitting a new plug.

- Working with electrical wires is dangerous, so take all possible safety precautions to avoid the risk of electrical shock. Never handle a live wire!

- For safety, do not attempt to fix external cords by twisting them together, capping them with wire nuts, and covering them with electrical tape. This will work for splicing wires inside your wall or junction box, but it doesn’t insulate external cords to prevent fires or electric shock.